The compact induction curing oven only needs electricity and works practically maintenance free. It is easy to install and operate. You are creating zero CO2 and NOx emissions, the handling of gas supplies in your production plant belongs to the past and you save gas costs.

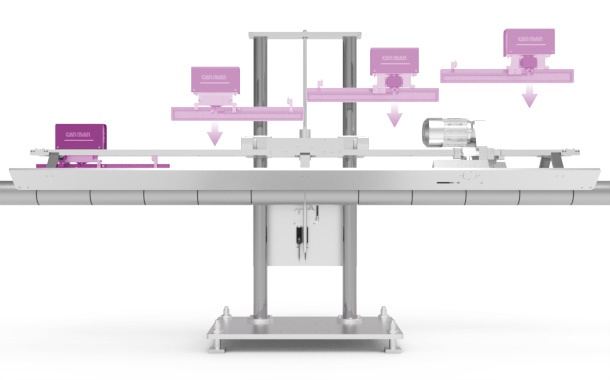

Each „generator – coil“ – unit offers individual power adjustments via a newly designed and easy to understand HMI (touchscreen) and thanks to their small size up to 4 of these units can be fitted into a 3 m PowerCURE™-module.

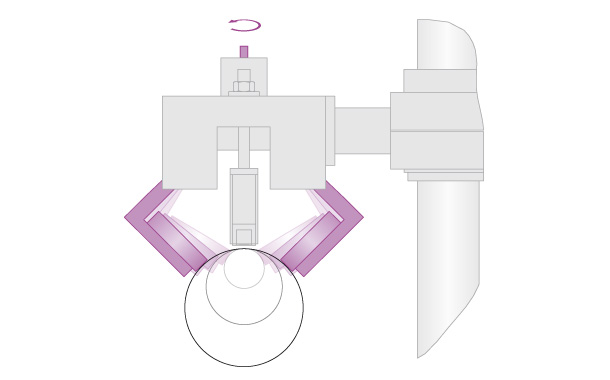

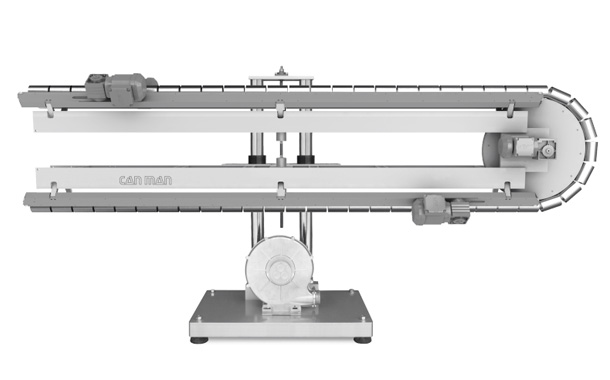

Both conveyors are linked together and adjusted via a centralized spindle mechanism. Whatever diameter you adjust, the gap to the induction coil remains the same. A canbody height change does not require any interaction except a speed and power change is planned (if not already connected with the welder).

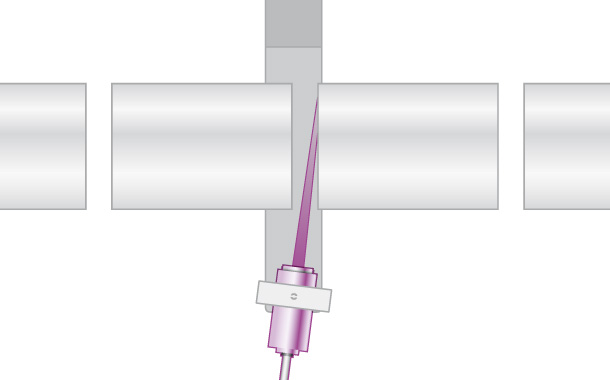

An IR sensor (infrared measurement) can be placed between every 3 meter module in order to monitor the temperature after every section. If a temperature variation is detected a warning is indicated and a controlled production stop will be initiated.

With the U-shape composition the needed space can be reduced by up to 50 %. Furthermore are the cured canbodies returning to the operator so that an immediate check without walking along the oven is possible.

| Production | Up to 90 m/min |

|---|---|

| Diameter range | 45 - 330 mm |

| Height range | 50 - 700 mm |

| Format change | 1 minute per module |

| Curing length | Depending on welding speed and type of seam coating |

| Adjustable to welding heights | 800 - 1300 mm above ground level |

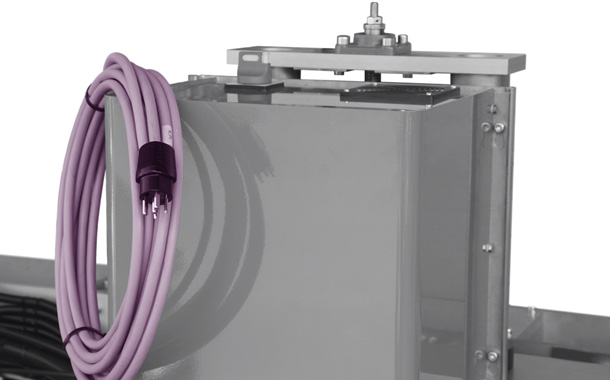

| Electrical mains | 3 x 400 VAC + N + Ground, 50 / 60 Hz |

| Fuse & Power | Depending on curing length |